Many manufacturing companies encounter a range of challenges that hinder their productivity and customer satisfaction. These challenges range from production issues like high volume of backlog orders awaiting production, excessive work-in-progress (WIP) inventory buildup before bottleneck processes, higher manufacturing costs resulting from material wastage and capacity to customer issues like longer delivery lead times compared to industry peers, dissatisfied customers due to delayed deliveries, a lack of visibility into order status and current demand and ultimately leading to inventory issues like excess inventory of non-moving materials and stock out of moving materials.

There are several off the shelf products for production planning in the market. However, they have limitations while configuring the tool for client’s specific constraints. The reason for this gap is most of the products are developed for standard controlled environment without the specific nuances. A production planning tool developed for one industry doesn’t really fit another. Even within the industry production set up between two companies are often different and hence the final customisation to suit the ground reality makes a big difference in the effectiveness of the tool.

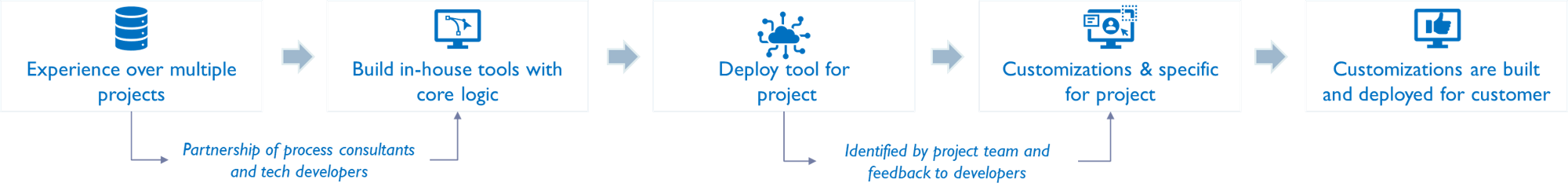

At Qwixpert, we specialize in addressing these challenges and enhancing production planning to optimize between capacity utilisation, inventory, and service levels. Through our extensive experience working with companies employing various manufacturing processes such as discrete, batch, continuous, batch + continuous, or a combination of these, we have developed an in-house Production Optimizer. This solution effectively tackles the aforementioned issues, regardless of the problem’s complexity, while considering constraints and specific business requirements.

Objectives:

- Optimizing the sequencing of orders based on priority and other business constraints:

- Right sequencing at processes before bottleneck process so the bottleneck process is not waiting for orders.

- To maximise the utilization of the bottleneck process to by optimising the number of changeovers (i.e., reducing idling)

- Reduction of delivery lead-time and Improved adherence to service level commitments.

- Improved visibility of order status from the structured planning to take a trade-off decision based on type of order to cancel, prepone, post pone based on changing customer demand or new orders. Improved communication with customer.

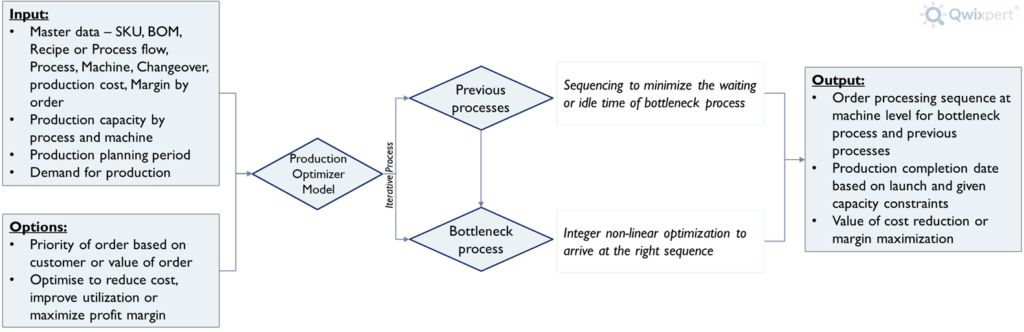

Logical Flow of the Production Optimiser

Our tool revolutionizes optimization approaches by providing an array of customizable features that surpass traditional methods:

- Problem Structuring: Our production optimization tool begins with meticulously identifying crucial parameters that determine the constraints of your business. We then expertly formulate and structure the problem, blending customization with our adaptable templates to achieve optimal results.

- Our production optimization approach provides the flexibility to optimize based on specific objectives: maximizing utilization, maximizing margin, or minimizing costs, all centred around identifying and addressing the bottleneck. Furthermore, our tool effectively aligns processes preceding the bottleneck to minimize downtime, ensuring uninterrupted productivity and optimal resource allocation.

- Let us consider a situation where a manufacturing company has a complex setup: a bottleneck process comprising of 5 machines, with multiple changeover parameters based on product characteristics and material supplied from different preceding processes. Additionally, the preceding process follow a non-linear sequence to reach bottleneck and each process may have multiple number of machines. For a given planning period the company needs the production sequence for 100 orders across the 5 machines at the bottleneck, this can translate to solving for over 1 million decision variables at a time, adhering to the constraints dictated by the company’s unique business requirements. Rest assured, our capabilities extend beyond this level of complexity, enabling us to tackle even more intricate scenarios.

With system-based planning gain the flexibility to adapt to changes in customer demand, supply chain disruptions, or other unforeseen events and better commitment & visibility to customer on supply on material for higher customer satisfaction.

The tool is built to be:

- Scalable: Ability to handle any type of process and number of processes with single or multiple machines and any number of orders

- Customisable: Ability to include multiple changeover parameters, priority, production constraints as per business requirement

- Modular: Use of the sequence to arrive at schedule by process and machine with lower idle time of the machine or waiting time of the order at bottleneck process and previous processes